With the arrival of winter, metals and exposed surfaces must withstand conditions that can compromise their durability and performance.

At Gi Di Meccanica, each component is prepared to effectively resist cold, humidity, and aggressive agents through a series of finishing processes designed to enhance long-term protection. Below is an overview of the treatments we use most frequently.

ZINC COATING (ZINC PLATING)

One of the most common treatments for steel is zinc coating. At Gi Di Meccanica, we use barrel electroplating (acid and alkaline), available in white, black, and yellow finishes.

Regardless of appearance, they all provide the same protective principle: zinc oxidizes more slowly than iron and steel, forming a barrier that protects against oxidation and humidity. It continues to offer protection even in the presence of small scratches thanks to cathodic protection.

Salt spray resistance: 1 μm withstands 24 hours before red rust

Standard thickness: 5÷12 μm

ZINC COATING + PASSIVATION

Zinc-coated components are immersed in a solution of trivalent chromium and nitric acid (pH around 1.8) for approximately 90 seconds. A film of 0.1÷0.3 μm composed of chromium oxides and zinc chromate forms on the surface.

Passivation increases corrosion resistance, and immersion time is proportional to the required hours of white corrosion resistance.

Example: a component must remain in the passivation bath for about 90 seconds to achieve approximately 50÷70 hours of white corrosion resistance.

Additionally, 1 μm of zinc coating corresponds to around 10 hours of resistance in salt spray testing before red corrosion appears. Red corrosion begins once the passivation layer (white corrosion) has deteriorated.

Since passivation creates a thin protective film, caution is required when handling the components to prevent surface damage (e.g., film cracking).

Salt spray resistance: > 150 hours

ZINC–NICKEL COATING

When greater resistance is required, especially in the presence of highly corrosive environments, we use zinc–nickel coating.

This electrolytic process deposits an alloy with a controlled nickel percentage (12÷17%), providing a harder, more stable, and more durable layer compared to standard zinc plating.

It is recommended for components exposed to severe operating conditions and high thermal cycles, where standard protection may not be sufficient.

Salt spray resistance: > 700 hours

ANODIZING

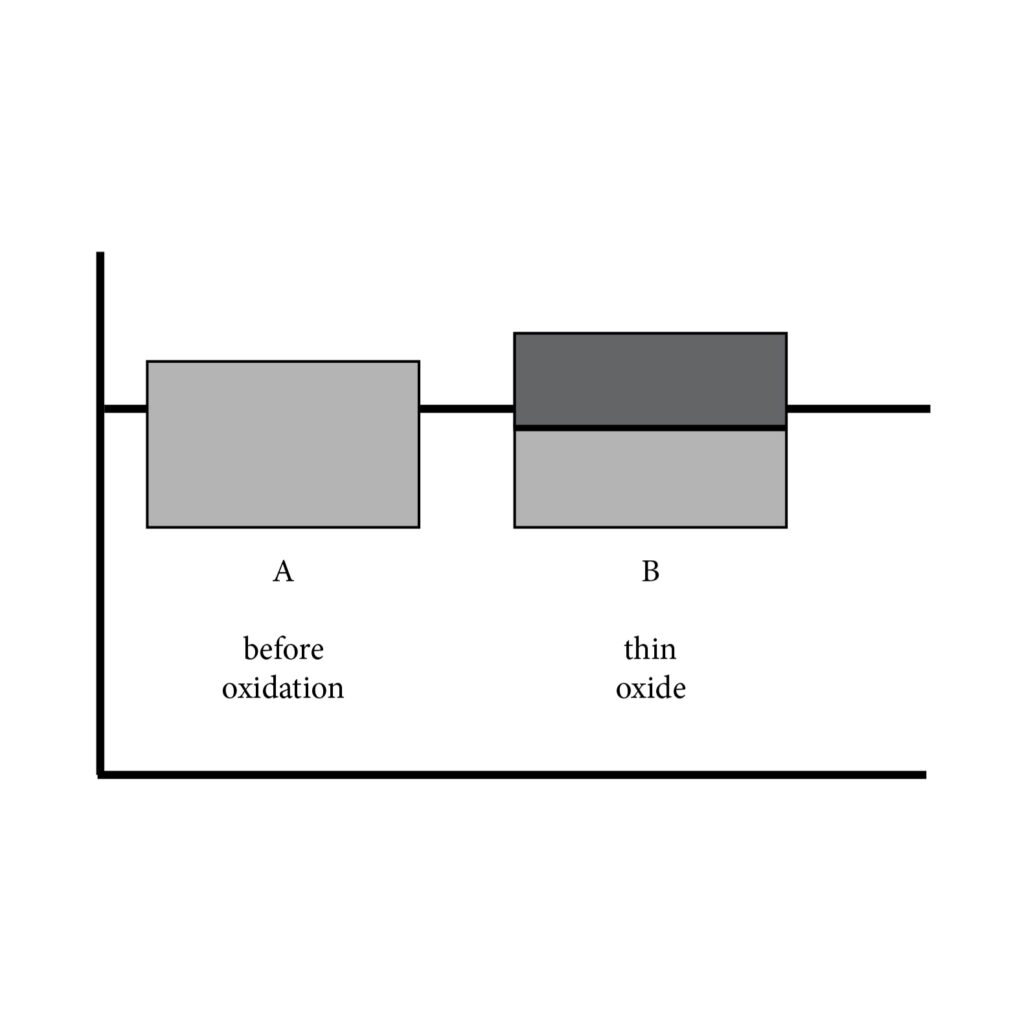

Anodizing is an electrochemical treatment specifically for aluminium. Unlike a coating that sits on the surface, it modifies the material itself: the anodic layer becomes an integral part of the substrate, increasing wear and corrosion resistance.

The process involves several stages including pretreatment, anodizing, optional colouring, and final sealing. It is widely used where strength, durability, and lightness are required.

Thickness: 10÷20 μm

Hardness of oxidized layer: 150÷250 HV

PAINTING (POWDER OR LIQUID)

It offers a more precise aesthetic finish and thinner coatings, ideal for complex geometries. Its scratch resistance is lower than powder coating.

Thickness: 40÷60 μm

CATHODIC ELECTROCOATING (CATHOPHORESIS)

Cathodic electrocoating is an extremely effective treatment: components are immersed on a frame in an electrophoretic bath and coated uniformly, reaching even the most complex areas.

It guarantees excellent corrosion protection and is often used as a primer before painting.

At Gi Di Meccanica we use exclusively black cataphoresis.

Salt spray resistance: 300 hours

Thickness: 12÷40 μm

The resistance of our components does not come solely from material selection but from a carefully designed finishing process that protects them over time.

Thanks to a combination of targeted treatments, Gi Di Meccanica ensures components that are ready to withstand any condition.